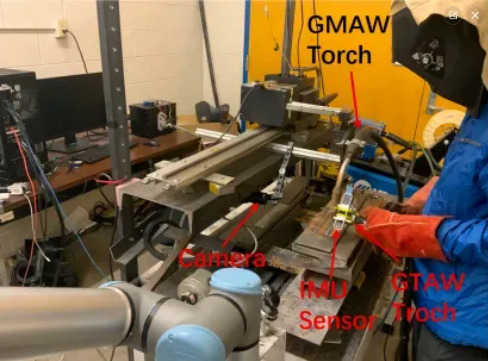

In two-electrode gas-shielded metal arc welding (DE-GMAW), precise control of the position of the torch and bypass electrodes is essential. For this process, the research team proposed the installation of a miniature Inertial Measurement Unit (IMU) sensor and camera to record the movement and fine-tuning of the welder's control of the torch.

In the experimental system for learning the operation of a human welder, the IMU sensor is mounted on a welding torch. Deep learning models were trained with weld images and IMU sensor data. This setup allowed the research team to easily access a large amount of data for model training. In this way, the robot can learn the welder to make precise adjustments to the torch position and attitude by focusing on the arc light in the weld image. With this revolutionary technology, more precise welding operations can be performed.