Despite ongoing efforts to improve workplace safety, the construction industry remains one of the most dangerous industries in the world: The percentage of work-related fatalities or fatal work injuries in the construction industry is 25%. Of these fatal injuries, approximately 36% are caused by falls from heights, one of the leading causes of accidental death among construction industry workers. Other countries - including Australia, China and South Korea - also incur significant economic, production and personnel losses from falls from height.

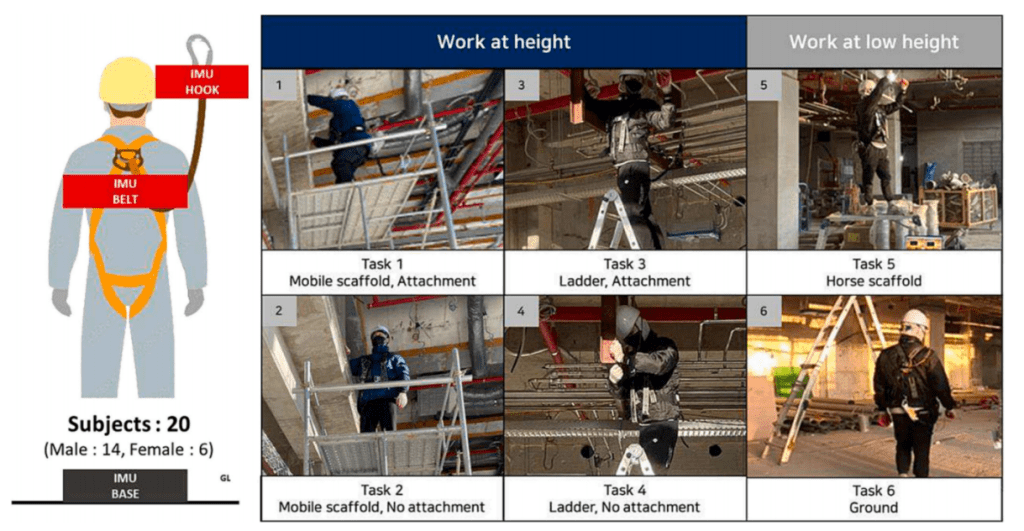

To prevent falls from heights, the Hunsang Choo research team from South Korea developed an automatic monitoring system. The system consists of a base module installed on each floor, a harness module, and a safety hook module worn by the worker (Figure 1, left). Barometer sensors and IMUs (inertial measurement units) are embedded in each module. The system estimates the worker's height based on the atmospheric pressure measured by the barometer and the data collected by the IMU, and determines the looseness of the safety hooks for workers at height by using the data collected by the IMU and machine learning algorithms.

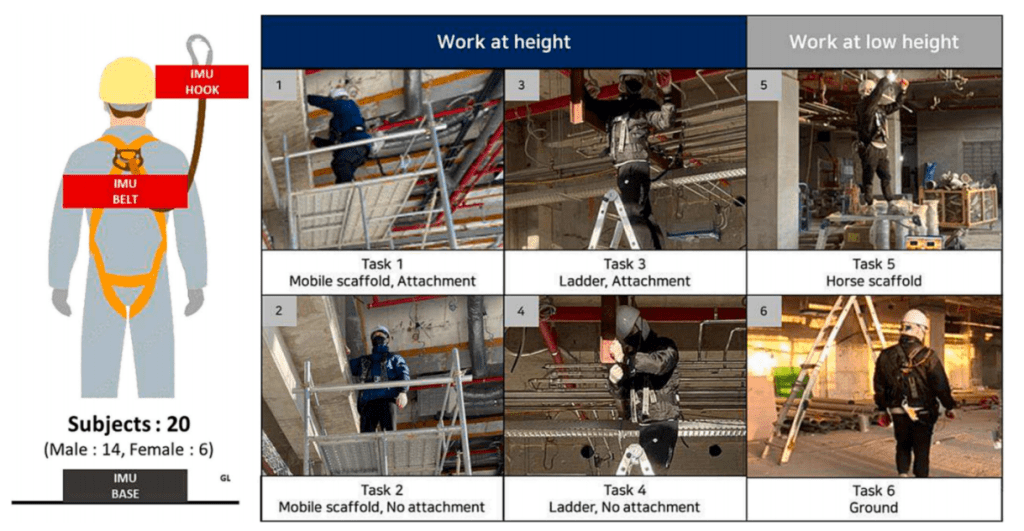

To validate the system for this study, the team conducted field experiments. Figure 2 lists the four types of work at height and two types of work at lower heights that were performed in the field experiment. Since the mobile scaffolding and ladder tasks were performed above 2m, they were categorized as high altitude work and further classified as safety hooks firmly attached and safety hooks not attached. Trojan frames and ground tasks are classified as lower height work.

Participants performed six tasks twice, and to avoid possible data bias from a fixed experimental order, the order of the tasks was randomized, each scene took three minutes, and the experiment lasted three weeks.

The performance of the model was evaluated using a leave-one-out cross-validation process after filtering the data collected from 20 construction workers at actual construction sites to remove outliers and eliminate noise. The results show thatThe accuracy rate of the aerial work identification system is 96%, and the accuracy rate of the safety hook attachment detection system is 86%.

The safety monitoring system in this experiment (combining the worker overhead identification system and the safety hook attachment detection system) has an identification accuracy of 83%, which is sufficient for efficient use in practice. The system can help the safety supervisor at the construction site to monitor the looseness of the safety hooks of the workers at height and effectively prevent the accident of falling from height.

[Choo H, Lee B, Kim H, et al. Automated detection of construction work at heights and deployment of safety hooks using IMU with a barometer[J]. Automation in Construction, 2023, 147: 104714.]